Coffee Roasting Explained

Posted by NAVEEN MUWAL

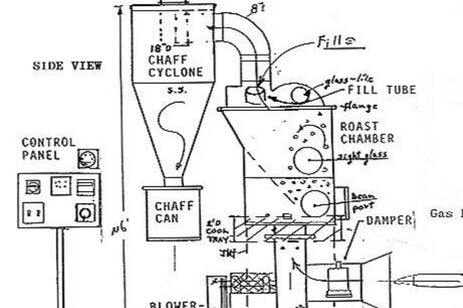

Coffee roasting is both art and science. Our master roaster has over 2 decades of personal experience and collectively our roasting team has almost a century of experience between them. The unique advantages of our fluid bed roasting method means that we can roast more efficiently and cleanly than other methods. The result is a smooth, rich flavor that never tastes burnt or unnecessarily bitter. Our goal is a pure flavor that reflects the true essence of the bean. The efficient heat transfer possible with hot air roasting results in a quicker overall roast time.

Regardless of the roasting method, the process consists of alternating endothermic and exothermic processes or absorbing and releasing heat and stopping the roasting process through rapid cooling at precisely the right times.

Endothermic, Warm Up

During this “warm-up” process, moisture is quickly being dissipated. In the fluid bed method, this happens very rapidly, minimizing the formation of acidic compounds that are the result of moisture in the coffee bean exposed to high heat for an extended period of time. The aromas you would experience include wet hay or grass to toasted grain. The bean turns pale to tan to light brown to brown. The Maillard Reaction is key in the bean reaching a milk chocolate brown color. It is the same reaction that browns beef under heat.

Exothermic Reaction, First Crack

Up until this point, the bean is absorbing heat - endothermic. The first crack is the opposite; it is the release of heat energy - exothermic, and occurs when the bean has reached an approximate internal temperature of 401 degrees fahrenheit. The bean is now twice the size, has shed the majority of its silverskin or chaff and begins to release carbon dioxide. Pyrolysis is now occurring and will continue through the second crack; in other words there is a chemical change that cannot be reversed. The beans are dry in appearance with no oils visible. A Cinnamon or light roast is the beginning of the first crack.

Endothermic, Recovery

This brief stage after the first crack must be as short as possible so it does not to stall the roasting process. Around the 356 degree mark, caramelization of the sugars has begun and the continuation of this process is the difference between the bean being roasted or baked moving forward. In this case as in the warm-up phase, the fluid bed roaster has an advantage, adding heat more effectively to quickly move the bean to the second and final crack. Between the first and second crack is anywhere between 15 and 30 seconds, so heat transfer is critical.

Exothermic Reaction, Second Crack

The second crack or release of heat energy typically happens at an internal bean temperature of 437 degrees fahrenheit. From the first signs of the second crack to its completion can be a period of 25-45 seconds. Full City or Medium roast is at the first signs of the second crack. Continuing through the second crack results in Vienna, French and Italian roasts, progressively.

Cooling

At the appropriate roast level, it is critical to cool the coffee and stop the roasting process. In the worst case scenario, beans can be baked or burned after removal from the roaster. We continue our air-influenced process by using fans and vents to rapidly circulate cool air over the beans. The process ensures that accurate bean temperatures / roast levels are as intended.

TAGS:

Longbottom Coffee & Tea

Longbottom Coffee & Tea